OEM Supply Powder Metallurgy Oxygen Probe - Nernst L series non-heated medium and high temperature oxygen probe – Litong

OEM Supply Powder Metallurgy Oxygen Probe - Nernst L series non-heated medium and high temperature oxygen probe – Litong Detail:

Application range

The Nernst L series non-heated medium temperature oxygen probe is used to measure the oxygen content in various sintering furnaces, powder metallurgy sintering furnaces and heat treatment furnaces. The applicable flue gas temperature is in the range of 700°C~1200°C. The outer protective material is superalloy.

The probe can be directly connected to Nernst’s oxygen analyzer. It can also be equipped with oxygen analyzers and oxygen sensors produced by other companies. The oxygen probe can measure oxygen in a wide range, from 10-30 to 100% oxygen content,and can be used to indirectly measure carbon potential.

Specifications and technical parameters

• Model: L series non-heated medium temperature oxygen probe

• Shell material: Superalloy

• Application flue gas temperature: 700°C~1200°C

• Temperature control: Furnace temperature

• Thermocouple: Type K , J , S ,R

• Installation and connection: The probe is equipped with 1.5 “or 1″ thread. The user can process the matching flange of the furnace wall according to the attached drawing in the instruction manual.

• Reference gas: The gas pump in the analyzer supplies about 50 ml/min. Use the gas for the instrument and supply the gas through the pressure reducing valve and float flow meter provided by the user. The manufacturer provides the PVC connecting pipe from the float flowmeter to the sensor and the connector at the sensor end with the transmitter.

• Gas connection pipe: PVC pipe with an outer diameter of 1/4″ (6.4mm) and an inner diameter of 4 (mm).

• Check gas connection: The sensor has an air inlet that can pass check gas. When it is not checked, it is closed by a bulkhead. When calibrating the air, the flow rate is controlled at about 1000 ml per minute. The manufacturer provides 1/8″NPT threaded pipe joints that can be connected to PVC pipes.

• Zirconium battery life: 4-6 years of continuous operation. It depends on the flue gas composition and temperature.

• Response time: less than 4 seconds

• Filter: Without filter

• Probe protection tube outer diameter: ¢18 (mm)

• Probe junction box temperature: <130°C

• Probe electrical connection: direct plug socket type or aviation plug socket.

• Weight: 0.45Kg plus 0.35Kg/100mm length.

• Calibration: After the initial installation of the system is stable, it needs to be checked once.

• Length:

| Standard model | Explosion-proof model | Length |

| L0250 | L0250(EX) | 250mm |

| L0500 | L0500(EX) | 500mm |

| L0750 | L0750(EX) | 750mm |

| L1000 | L1000(EX) | 1000mm |

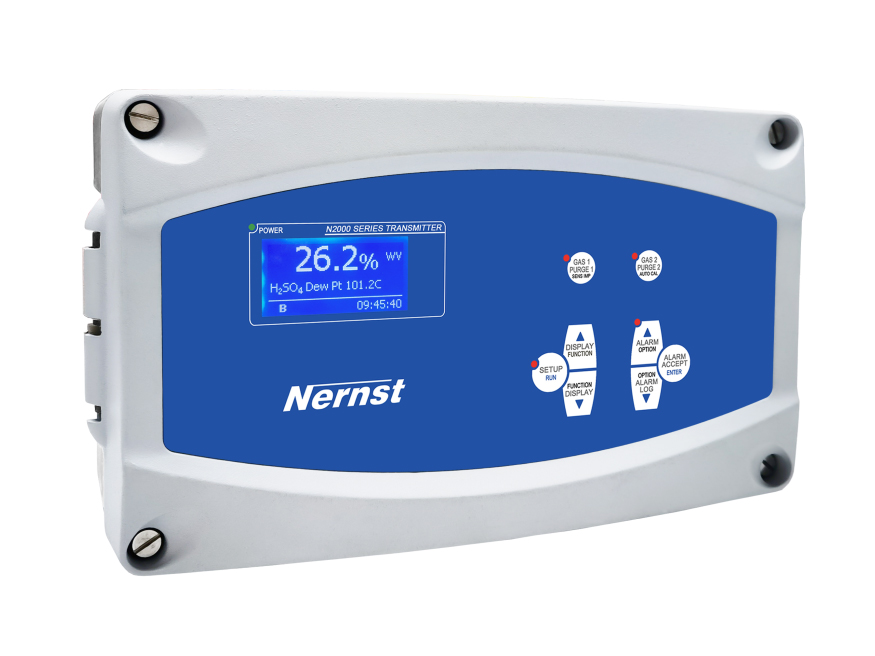

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for OEM Supply Powder Metallurgy Oxygen Probe - Nernst L series non-heated medium and high temperature oxygen probe – Litong, The product will supply to all over the world, such as: Washington, Argentina, California, We look forward to hearing from you, whether you are a returning customer or a new one. We hope you will find what you are looking for here, if not, please contact us immediately. We pride ourselves on top notch customer service and response. Thank you for your business and support!

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!